Crane fuel saving and RTG electrification

Reduce costs and environmental impact

Fuel cost is one of the main factors determining your total cost per move. Electrification of your existing diesel rubber-tire gantry cranes (RTGs) can reduce fuel costs significantly.

Reduce RTG fuel consumption by up to 95% with electrification

Electrification of RTGs reduces emissions and can reduce fuel costs by as much as 95 percent. The return on investment can be less than two years.

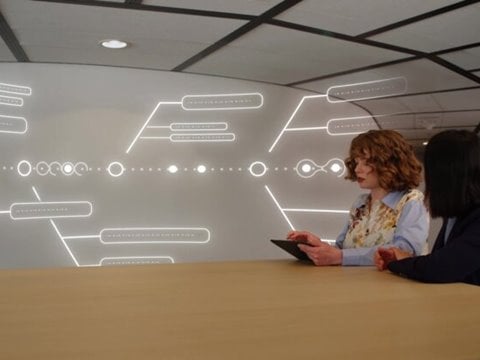

We are able to supply a turnkey electrification solution for all brands of RTG cranes. Kalmar experts work with you to specify a solution that meets your operational needs and ensures the optimum return on investment. Working with Kalmar means you can take advantage of the best technology and solutions on the market. We are completely independent and can advise on the electrification of all brands of equipment. A turnkey project includes the design and supply of power grid connections, substations, a conductor-bar system, or cable-reel integration, taking into account the full chain of interacting components. The two main types of E-RTG conversions are cable reel and conductor bar. Cable-reel conversion: In cable-reel (400 V–13 kV) designs, a power transformer is usually installed on the crane to reduce the substation voltage to the E-RTG motor supply voltage. The power feeding point can be at the end or center of the container stack, or a combination of the two. For crane retrofitting, the diesel generator can either remain in place or be removed. If it is removed, block changes and driving to maintenance areas require an auxiliary genset or batteries. Conductor-bar solution: Busbar designs (400–1,000 V) require the installation of a steel support conductor bar assembly along each of the terminal’s stacking areas. Low voltage cables feed power from the substations to the busbars. A power cable can be manually plugged into a collector trolley, which is pulled along the busbar when an RTG is operating. Alternatively, an automatic arm-collector assembly is integrated into the RTG. This arrangement eliminates the need for human intervention and therefore enables faster stack changes.

![]()

Why a cable reel system?

With a cable reel system, you could benefit from a smaller overall yard size, as you won’t need to install a fixed conductor line. This system gives you more flexibility when extending your stack length, while the cables are also capable of carrying high-speed data for remote monitoring and future automation.

Why a conductor line system?

Conductor line conversions are ideal if you regularly need to move your RTGs between container blocks. This type of system makes it easy to add or remove cranes within the same block and change the lanes being used, and also provides easy access at the stack ends. What’s more, just as with a cable reel system, the cables used are also capable of carrying high-speed data.

![]()

We’re here to help

Get in touch with us to learn more about our services and how they can support your business.

![]()