DP World Antwerp Gateway finds efficiency in the cloud

DP World’s Antwerp Gateway uses Kalmar Insight to collect and analyse the data from their port activities, so they can take action to improve safety, performance and sustainability.

With a capacity of 2.8 million TEU, DP World’s Antwerp Gateway is a busy place. They need useful and reliable information about all this activity in order to better understand exactly how their operations are running and where to make improvements. The innovative technology of Kalmar Insight allows them to turn data into a valuable resource in order to improve efficiency, safety and productivity.

“We need to receive correct information quickly so we can take appropriate action. We also need that data to be transparent and as easy to use as possible,” explains Jurgen Van Remoortere, Automation Manager for DP World Antwerp Gateway. “We saw that Kalmar Insight was the solution we needed.”

Benefit immediately

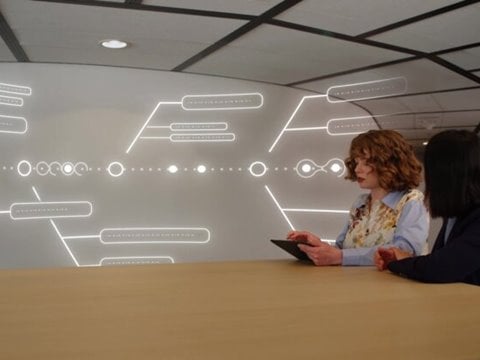

Kalmar Insight is a cloud-based performance management tool for cargo handling operations. It collects data from multiple sources and provides actionable information in a user-friendly, versatile dashboard. DP World Antwerp Gateway uses APIs and creates their own layouts.

“It is easy and logical to use. The interface is user-friendly and not complicated, so you don’t need lots of training,” says Jurgen De Breuck, Manager Rolling Equipment and Welding at DP World Antwerp Gateway. “We had a foreman who used it immediately after receiving his username and password.”

“We need to receive correct information quickly so we can take appropriate action."

The information can be accessed via whatever screen you choose, such as desktop, notebook or mobile. DP World Antwerp uses Kalmar Insight to see their equipment’s real-time operations as well as historical activity. They can change their view from one machine or one operator all the way up to their equipped fleet of 58 Kalmar Straddle carriers.

Building digital foundations for the future

One of the main benefits DP World Antwerp Gateway has received is time. They use Kalmar Insight to optimise maintenance and avoid downtime by improving the reliability and availability of their equipment. They also save time by using the platform to improve fueling processes. By improving efficiency and productivity they directly improve not only their sustainability but also their profitability.

“By gathering quality data this helps us to create future innovations, like automation solutions.”

Gathering and analysing data gives immediate concrete benefits, but it can also lay the groundwork for even more improvements in the future. DP World Antwerp Gateway already has some ideas in mind.

“By gathering quality data this helps us to create future innovations, like automation solutions,” says Van Remoortere. “We can also add other things in the future to improve safety, like stability control. This will help us remove human errors and build for the future.”

Related articles

Further reading

Subscribe and receive updates in your email

Subscribe