Raising the bar on forklift flexibility

Since the first machine rolled off the production line in 1949, Kalmar forklift trucks have become synonymous with build quality, low service and maintenance costs, and customisation.

Kalmar forklift trucks can be found operating at the world’s largest ports and terminals, and they are also a popular choice for companies in the mining, metal and forestry industries, in Europe in particular, but increasingly across other parts of the world, too.

“We offer a wide range of trucks with different load centres and lifting capacities of up to 72 tons, the highest on the market,” explains Alejandro Martinez, Sales Director North and West Africa.

The company has sold more than 30,000 units worldwide to customers looking for a machine built with quality parts on a robust chassis with a standard driver interface and a common electrical system.

“Safety is paramount”

Kalmar has been in the vanguard of electric powered vehicle development over the last 30 years. The electric forklift truck fleet can handle up to 18 tons and remains one of the few fully electric options for customers requiring a medium range machine.

“Safety is paramount,” says Martinez, “All cabins are designed for maximum visibility with secondary doors for emergency exit, three point access, and non-slip surfaces.”

The machines are also designed for easy maintenance. In response to clients’ differing maintenance resources, interventions have been simplified through easy access servicing points, while 500 hour service intervals maximise availability and reduce the total cost of ownership.

“All cabins are designed for maximum visibility with secondary doors for emergency exit, three point access, and non-slip surfaces.”

Ease of use

Customers have access to Kalmar Care for service and technical support. Using genuine Kalmar parts is vital to maximising the life expectancy of each machine and Kalmar’s parts service ensures customers have the parts they need when they need them.

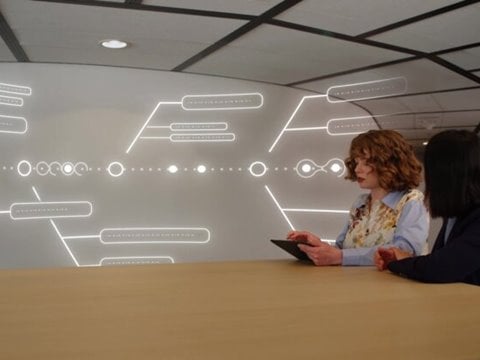

Customers can also access Kalmar Insight, a performance management tool that aggregates data from multiple sources to provide an overview of fleet operations and maintenance needs.

The Kalmar Academy is an additional resource where operators can learn how to use the machines for maximum efficiency.

“Kalmar forklift trucks are generally not the cheapest machine on the market, but any extra costs are offset by their reliability and the low TCO (total cost of ownership),” adds Martinez. “They are the clear choice for a customer looking for quality and performance at the right cost.”

“Container handling can be done with standard forks, but the machines can also be equipped with a 20-40 foot spreader for tank cleaning and container repair.”

Hans Larsson, Sales Support Manager, explains that users can easily customise their machines to handle specific tasks, such as fitting special attachments to prevent pipes from rolling off the fork.

“Container handling can be done with standard forks, but the machines can also be equipped with a 20-40 foot spreader for tank cleaning and container repair,” he says. “For the most challenging operating conditions we have a large wheel machine with superior traction.”

One of the best examples of a challenging operating environment is the metal industry where the machines have to work in high temperatures and in the presence of liquid metal and dust. “Kalmar has a long history of collaboration with the steel and aluminium industries and we have developed a number of options for this segment,” Larsson adds.

Hans Larsson and Alejandro Martinez discussed the capabilities of Kalmar forklift trucks during a webinar hosted by Kalmar in March. A recording of the webinar is available at https://www.kalmarglobal.com/news--insights/webinars/kalmar-forklift-trucks--webinar/

Related articles

Subscribe and receive updates in your email

Subscribe