When safety is your driver.

Reduce collisions, accidents and damage.

Collisions and damage to Kalmar Straddle Carriers in your yard can cost your business time, money and have a negative impact on your operations and safety levels, which needn't be the case. With Kalmar’s Collision Warning System for Straddle Carriers, you can prevent and reduce the severity of collisions, damage and accidents, allowing your equipment to operate more efficiently and safely with minimal downtime.

Save time and money.

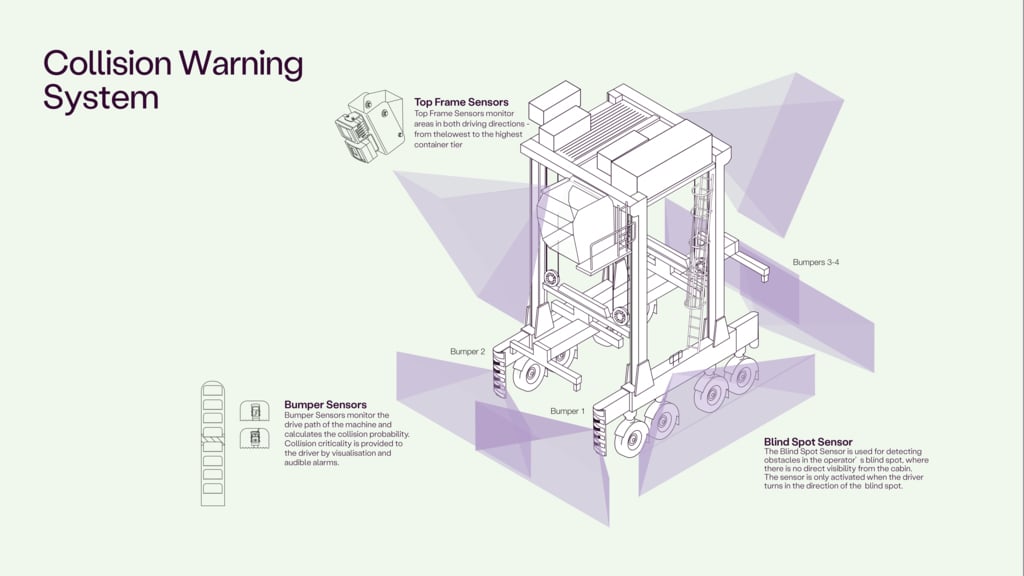

Our Collision Warning System uses sensors fitted to your Kalmar Straddle Carrier when working end-to-end or as shuttles to survey the surrounding area and actively warn your operator visually and/or with audible alarms of any obstacles in the path of your machine, its spreader or container being carried. Allowing your operators to take immediate evasive action to reduce the risks of collision, accidents and damage to your straddle carriers or containers, saving you time, money and extending the life of your equipment.

Reduce collisions, accidents and damage with the Kalmar collision warning system

DOWNLOADS

More than enhanced safety levels.

The Kalmar Collision Warning System not only makes operating your straddle carriers significantly safer to operate in your yards, it also delivers on many other fronts:

Keeping your straddle carriers and operators safe.

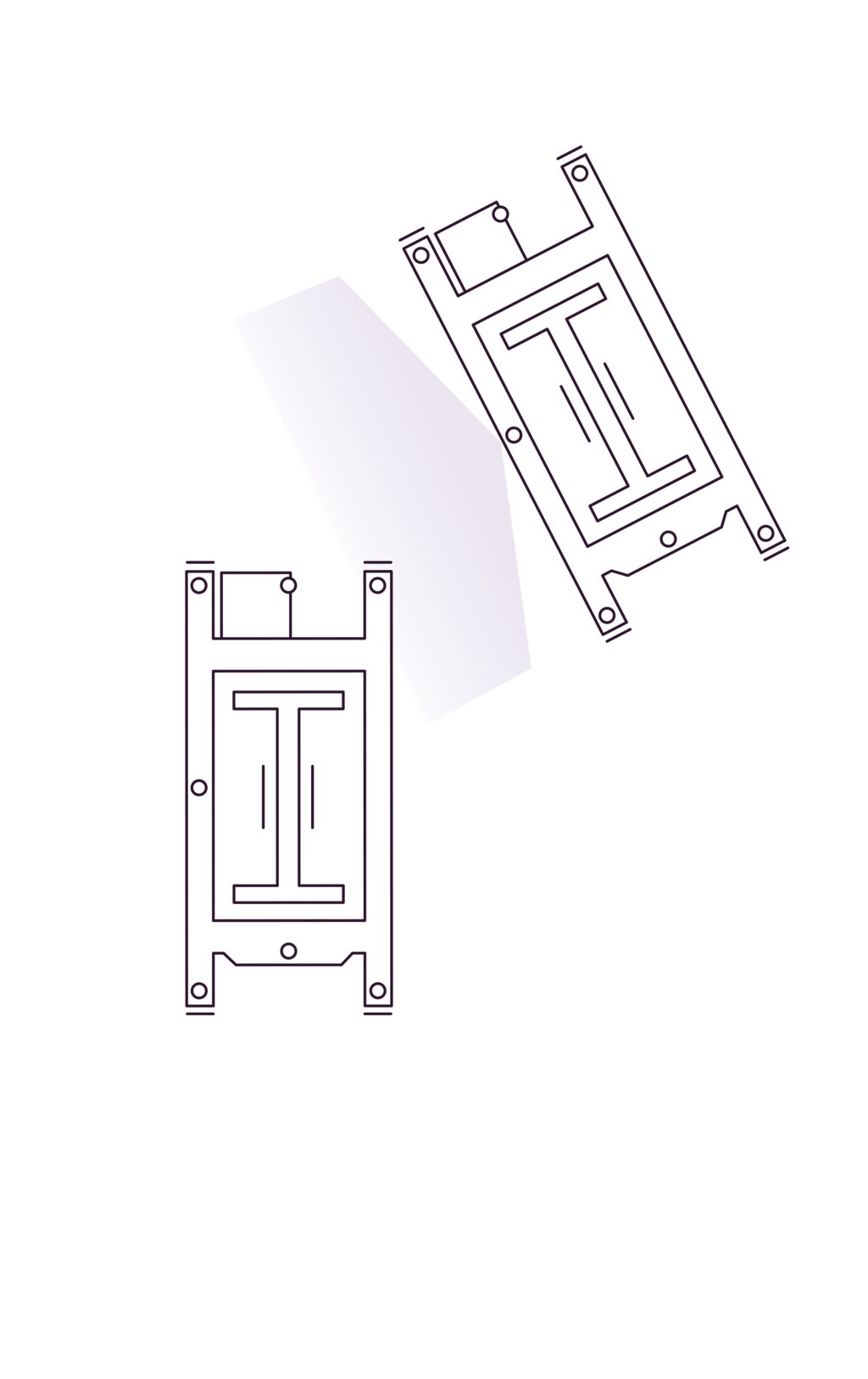

By fitting your straddle carrier with additional sensors on the top chassis, bumpers and side struts Kalmar’s Collision Warning System is able to:

- Detect and warn the operator of obstacles in the path of your straddle carrier.

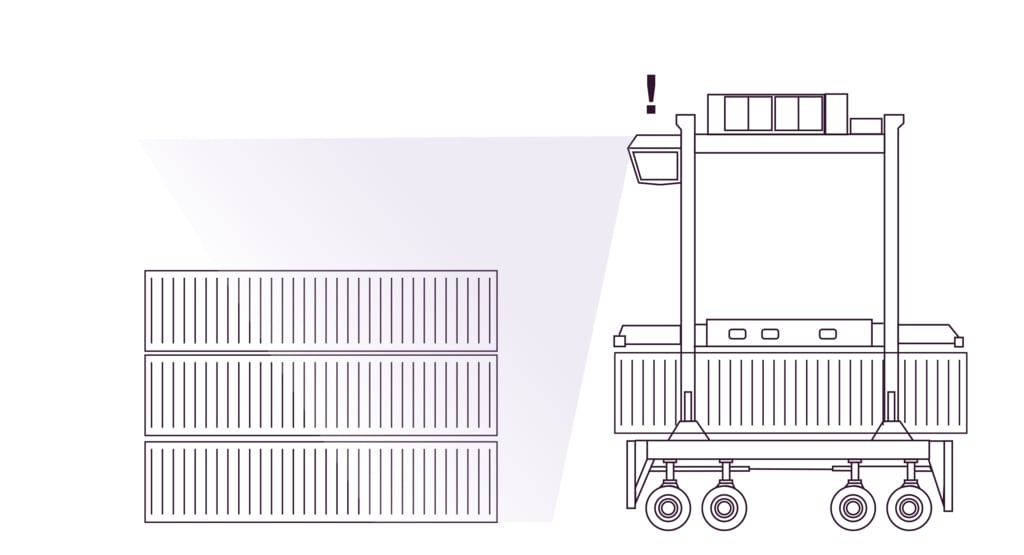

- Detect and warn the operator if the spreader and container are too low on your straddle carrier, when going towards a stack of containers.

- Detect and warn the operator of any obstacles or other straddle carriers that may be in their blind spot.

In cabin displays and warnings.

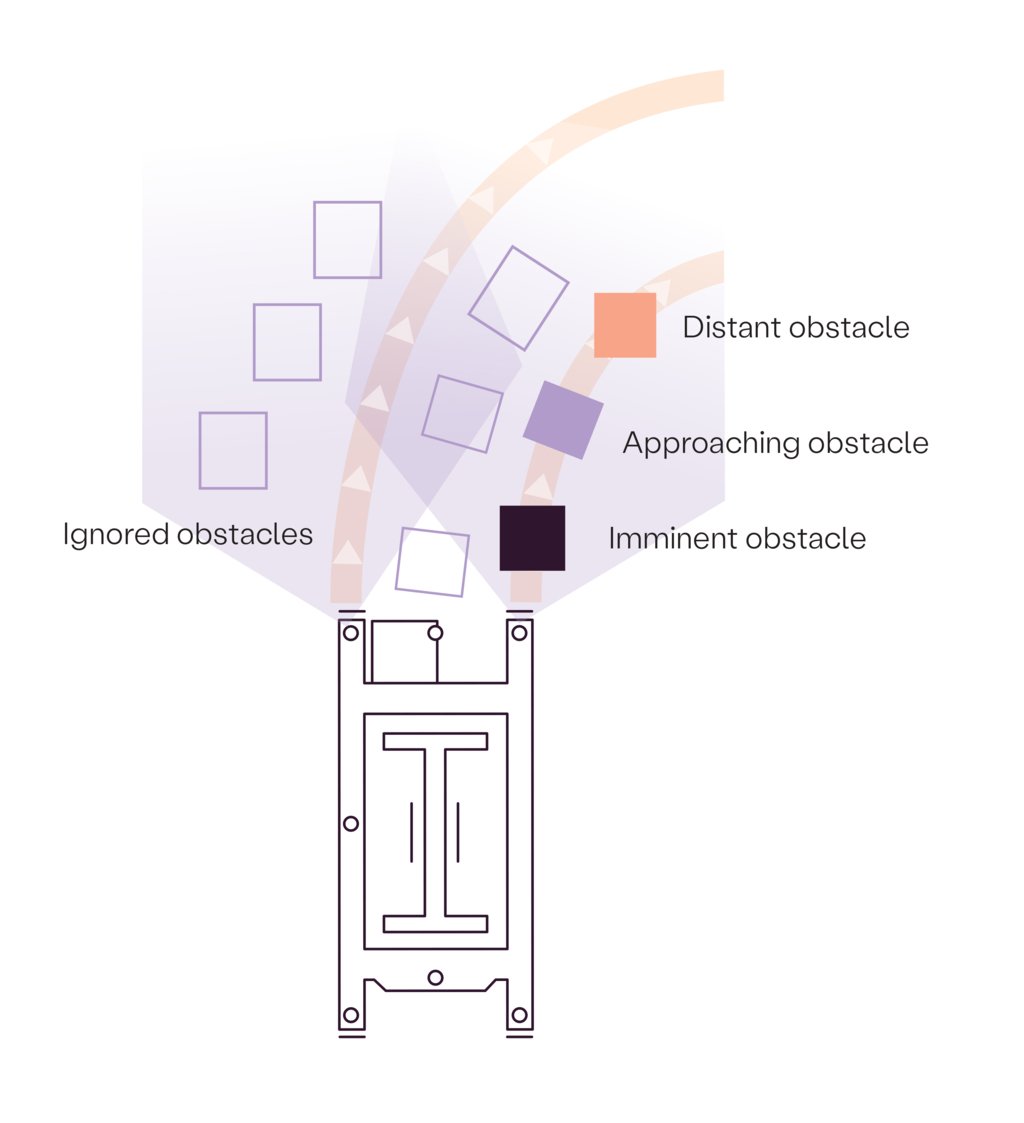

If an obstacle is detected, then an audible alarm will sound in the cabin alerting your operators of any danger. Any obstacles will also be displayed through a live view system mounted in your straddle carrier’s cabin. This display has three different display modes:

- Top: view from top chassis sensors

- Multi: view from side chassis and rear sensors

- Blind: view blind spot sensors.

Combined they can provide a clear view of any obstacles or dangers that may be in the path of your straddle carrier, helping to keep your equipment, containers, and operator safer by reducing the risk of any collisions, damage or accidents.

Frequently asked questions:

Can this system be fitted to my current Kalmar Straddle Carrier?

This system can be retro-fitted to Kalmar Diesel Electric, Hybrid and Electric Straddle Carriers that are operating in your yard, end-to-end or as shuttle carriers between your quayside and stacks. New Kalmar Straddle Carriers can be fitted prior to delivery with our Collision Warning System.

Can this system be fitted to Straddle Carriers made by other OEMs?

The Kalmar Collision Warning System can be retro-fitted to Straddle Carriers made by other manufacturers after undergoing a suitability assessment of your equipment to make sure its structure and systems are suitable. Once this assessment has been completed you will know if the system can be fitted.