From container handling to industrial, intermodal, and barge applications, discover the reliable and robust Gloria range of reach stackers

Lifting equipment that drives efficiency and reduces downtime

Our Gloria range of reach stackers embodies decades of expertise, beginning with the pioneering of the world's first commercial reach stacker in the 1980s. We’ve leveraged this extensive experience to enhance efficiency and reduce downtime, making it easier for you to lift, stack, and handle containers with ease. The most crucial insight we've gained from our years of experience is the importance of keeping your business moving, no matter the challenges.

Additionally, all Kalmar counterbalanced machines—including reach stackers, empty container handlers, and forklifts—have been upgraded to meet the EN 1175:2020 safety standard. This ensures maximum safety when operating any Kalmar machine throughout North America.

DOWNLOADS

Technical information

| Technical info | Kalmar DRG500-700 - Industrial handling |

|---|---|

|

Lifting capacity (lbs)

|

max 154000 |

|

Wheel base (inches)

|

256" - 295" |

|

Cab options

|

EGO |

|

Stacking (toplift)

|

- |

|

Engine

|

Volvo 355 hp/382 hp, Cummins 330 hp |

|

Stage emission

|

EU3/Tier 3, EU4/Tier 4F, EU5, KMOE5 |

|

Transmission

|

ZF 5WG, Dana TE-30500 |

|

Models

|

Tool carrier, Lifting hook |

What can you expect from the Kalmar Gloria range of reach stackers?

- Continuously improved performance and availability levels across the entire range of reach stackers.

- An ergonomically designed reach stacker cabin that offers more comfort and safety for your operators.

- A range of options that can help reduce your carbon emissions.

- A more connected experience with a variety of digital support services.

How have we improved the availability of the Gloria range of reach stackers?

With our latest generation of reach stackers, we’ve managed to boost performance once again with newly designed integrated components and improved operator interfaces. Each model in the Gloria range also features advanced components and a proactive monitoring system, delivering remarkable benefits to our operators worldwide. Kalmar reach stacker users in the United States have also experienced enhanced reliability and minimized downtime that our equipment brings to their material handling and logistics processes.

- Advanced Components: For example, our new segmented wiring makes maintenance and replacement simpler and quicker. With fewer exposed components, there is less wear and tear on wiring, hydraulics, and other connectors, enhancing the reliability and availability of your Kalmar Reachstacker.

- Proactive Monitoring: Kalmar was the first manufacturer to use CAN-bus technology as a standard. This technology automatically detects failures, compensating with backup bus wires and connectors before any fault can affect your reach stacker. The result is less downtime when handling materials or moving containers.

- Easier Maintenance: All major service points are accessible from the ground, and the engine bay has removable top covers, making routine checks and maintenance tasks quicker and safer.

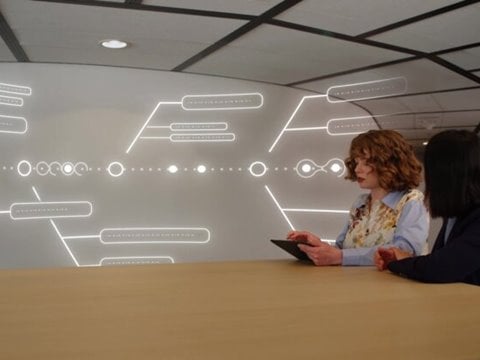

Will your operators benefit from our new EGO Reachstacker Cabin?

Keeping your operators safe and comfortable benefits both your employees and your business. Each of our Gloria Reachstackers is fitted with our ergonomically designed EGO cabin, providing operators with a safer and more comfortable work environment. We have improved the operator’s visibility with an open cabin design optimized for visibility at all angles. Smart profiles and curved windows offer excellent forward, diagonal, and rearward visibility. A range of optional cameras can be mounted in different positions on your reach stacker to enhance the operator’s view of their working environment. Additionally, every EGO Reachstacker Cabin is equipped with an adjustable seat, high-capacity wipers, an ergonomically designed joystick and steering wheel, comfort pedals to reduce leg strain, a climate control package for comfort, and an adjustable work console with an intuitive user interface.

A range of reach stackers ready to handle any load

The reliability, robustness, and success of Gloria’s platform have allowed us to expand our initial offerings to meet a variety of material and container handling needs. Initially designed as a top loader to handle containers, the Gloria range now includes reach stackers specifically designed for industrial, intermodal, and barge handling applications. To further reduce the carbon footprint, the Gloria family has expanded with the addition of the Kalmar Eco Reachstacker and the Kalmar Electric Reachstacker.

The Gloria range of reach stackers provides a wide array of choices, allowing you to select the right reach stacker based on your container lifting or material handling needs.

- Toplift – DRG450S: With an impressive lifting capacity of up to 99,000 lbs (45 tons), this reach stacker is expertly designed to move, stack, and handle containers with ease.

- Barge Handler – DRG450S: Boasting a lifting capacity of up to 99,000 lbs (45 tons) and a negative lift capacity of 54,000 lbs (27 tons) in the 4th row, this model excels in versatility.

- Intermodal – DRG450C: Our intermodal reach stacker, perfect for handling laden truck trailers and working on the second rail line, has the ability to lift loads up to 99,000 lbs (45 tons).

- Lift Hook – DRG570-1300Z: This reach stacker is fitted with a lift hook to move a variety of loads up to 286,000 lbs (130 tons), making it ideal for the heavy-duty demands of the steel and wind industries.

- Tool Carrier – DRG500-650A: With a robust lifting capacity of 143,000 lbs (65 tons), this Gloria reach stacker can be fitted with a range of attachments to meet your precise lifting needs. Contact our reach stacker sales team in North America to find the perfect attachment for your business.

Enhance your safety and eco-efficiency

Kalmar offers a wide range of options to further enhance the eco-efficiency, productivity, and safety of your reach stacker. Please contact our reach stacker sales team in North America to learn more.

Need parts or service support for your reach stacker?

Kalmar offers a large range of support services through MyKalmar, allowing you to order easily. You can also access Kalmar Insight, our fleet performance tool. Additionally, we offer a range of flexible service and support contracts that can be tailored to your exact needs.

Kalmar Reachstackers: elevating material handling efficiency in the United States and beyond

Kalmar has a rich history with reach stackers that began in the 1980s when it launched the world’s first commercial reach stacker. Over decades of innovation, Kalmar set new standards for lifting equipment in material and container handling, offering high performance, user-friendly operation, low running costs, and excellent environmental performance. By 2014, Kalmar had delivered more than 15,000 reach stackers worldwide, becoming a global leader with over 10,000 units actively operating in more than 160 countries.

Building on this success, Kalmar introduced the Gloria range of reach stackers to the United States in 2014, following successful launches in Europe and the Asia-Pacific regions, where Gloria models had already earned a reputation for superior productivity and cost-effective operation. The Gloria range brought decades of Kalmar's experience and innovation to North America, meeting the highest standards of performance, cost-efficiency, and safety. For instance, a standout model from the series is the Gloria Reachstacker DGR450-75S, which exemplifies these innovations with its advanced boom design, extended legs for handling containers below sea level, and an elevated cabin for better visibility.

Kalmar customers in North America and worldwide have consistently highlighted the Gloria reach stacker's ability to significantly enhance operational efficiency while reducing downtime, thanks to its robust engineering and innovative design. The advanced operator interface and ergonomically designed cabin have been particularly well-received, providing superior comfort and ease of use, which in turn boosts productivity. These attributes, combined with Kalmar's commitment to safety and cost-efficiency, have solidified the Gloria reach stacker's reputation as a top choice for container and material handling in North America.

Frequently asked questions

Can the Kalmar Gloria Range use HVO?

Kalmar Stage 3, 4, and 5 Gloria Reachstackers equipped with Volvo diesel engines are certified to use HVO Fuel, which complies with the EN 15940 standard. Switching to HVO Fuel can reduce your CO2 emissions by up to 90% from day one. For more information about HVO, click here.

How do I measure the performance of my Gloria Reachstacker?

Kalmar Insight provides real-time operational information about your Kalmar Gloria Reachstacker, allowing you to review and analyze performance data to improve operations. Kalmar Insight also helps you manage maintenance tasks more effectively with the Kalmar Insight Maintenance Module. For more details, click here.

Is the Kalmar Gloria Range of Reachstackers SOLAS compliant?

You can equip any of the Kalmar Gloria Reachstackers with the Kalmar Load Measurement System, which records the precise weight of every load your reachstacker handles and stores this information automatically in Kalmar Insight. This system is SOLAS compliant and can be retrofitted to most other reachstackers as well.