Experience eco-efficiency, productivity, safety, and a modular battery solution designed for your operational needs with the Kalmar ERG-420-450.

The time is now to go electric

Kalmar’s electrically powered reach stacker with lifting capacities up to 45 tonnes, can help improve the eco-efficiency of your operations while maintaining the highest levels of productivity and safety. With a range of modular battery options and charging solutions, we can work with you to design a solution that will deliver for your business.

Kalmar's most sustainable reach stacker

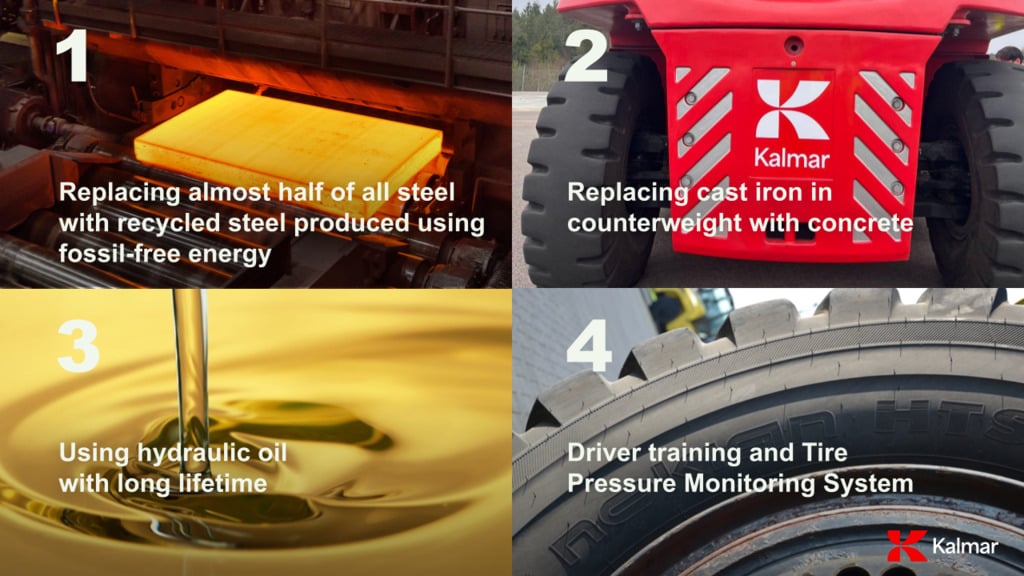

Kalmar has introduced new sustainability options for its customers:

Kalmar, using SSAB Green Steel, have designed and built Kalmar's most sustainable reach stacker by significantly reducing the carbon emissions produced during the manufacturing process.

By replacing almost half of the steel with green steel in the manufacturing process Kalmar has been able to significantly reduce the levels of embedded carbon in its electric reach stacker, making it Kalmar's most sustainable and eco-efficient reach stacker available.

Our goal is to make every Kalmar Reachstacker as sustainable as possible, which is why we are also introducing a new emission-reducing counterweight made from unprocessed naturally heavy material to replace the standard cast-iron counterweight, which will further lower the embedded carbon in the manufacturing of our entire reach stacker range. By providing Eco Driving Training to operators, promoting optimal tire pressure with our Tyre Pressure Monitoring System and by using long lifetime hydraulic oil you can further reduce your carbon emissions and improve the sustainability of your reach stacker.

What makes Kalmar’s most sustainable reach stacker:

Become Kalmar Eco Hero

Every Kalmar Electric Reachstacker you take delivery of will help improve the sustainability of your operations and cut your carbon emissions. To recognise the commitment that you and your business are making in building a more sustainable future, you will be awarded the prestigious Kalmar Eco Hero Award. (The first electric reach stacker delivered to Cabooter Group.) This award represents the efforts you are making in cutting your emissions and the appreciation from our team that you are helping to build a better, more sustainable future for us all.

Are you Kalmar’s next Eco Hero, what are you waiting for?

Kalmar's Electric Reachstacker

Shifting to electric? Your questions answered.

DOWNLOADS

Technical information

| Technical info | Kalmar ERG420-450 |

|---|---|

|

Lifting capacity (lbs)

|

max 99000 |

|

Wheel base (inches)

|

236" - 256" |

|

Cab options

|

EGO |

|

Stacking (toplift)

|

max 6 high, 4 deep |

|

Motor

|

BoschRexroth traction motor 182 kW/244 hp cont. - 405 kW/543 hp max |

|

Transmission

|

BoschRexroth 2-speed transmission |

|

Battery

|

Li-Ion, 4 options (245 kWh - 587 kWh) |

|

Models

|

Toplift, Intermodal |

Eco-efficiency built in

Being battery powered, your electric reach stacker will produce zero carbon emissions at source, making it cleaner and safer to operate.

You can lower your reach stacker carbon emissions even further by:

- Using green energy sources where available

- Generating your own power to charge the batteries.

Getting an electrically powered reach stacker is only the start of your eco-efficiency journey. We will be with you every step of the way.

Productive by nature

With an electric powertrain, your drivers will notice a big difference with faster and smoother acceleration and more responsive handling while still being able to lift up to 45 tonnes efficiently and safely.

Less time will be spent servicing and maintaining your electrically powered reach stacker as it has less moving and mechanical parts, plus you will be able to keep it running optimally within a broad range of temperatures with Kalmar’s Thermal Management System fitted as standard.

Kalmar’s Thermal Management System keeps your core battery temperature at 25-30°C within the following temperature range:

- Minimum -30°C

- Maximum 40°C.

Safety in focus

Kalmar’s range of electrically powered reach stackers offer:

- highly responsive handling and superior visibility from the cabin, helping to keep your driver safe and in control at all times

- reduced cabin noise and vibrations as our electrically powered reach stacker’s driveline is extremely quiet and smooth, reducing cabin noise

- an electrically powered high voltage system with encased and shielded high voltage lines. Should any connection be interrupted, the whole system will automatically shut down, keeping your team safe

- a large range of safety options available that can further enhance the safety of your drivers and reach stackers.

Modular by design

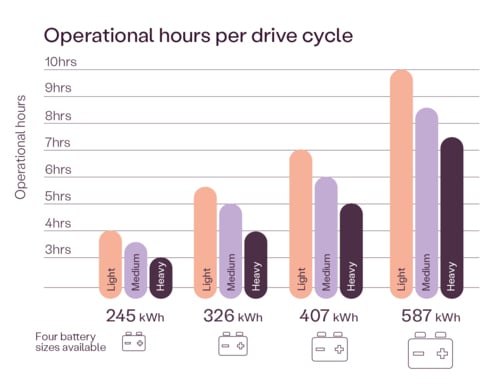

Batteries and chargers are a big part of your overall investment, making it critical you get a solution that is matched to your operational requirements. Which is why Kalmar has taken a modular approach to our battery and charging solutions.

There are four different battery options:

Our battery solutions all come with a 5 year warranty and have an expected 10-12 year first life [80% capacity left].

Kalmar electrification journey

Learn more about our journey towards electrification by watching our videos on the Green Chair.

Frequently Asked Questions

What battery should I choose for my Kalmar Electric Reachstacker?

Kalmar can help you work out which battery option and charging solution are right for your electric reach stacker based on your current work cycles.

How do I charge my batteries for my electric reach stacker?

There is a range of different battery charging solutions available, with a choice of different charging capacities and number of charging points in each unit. Once you have chosen the right battery solution, Kalmar can work with you to identify which charging solution is best suited to your drive cycles and electric fleet.

How can I monitor the charging as well as the state of the battery in my reach stacker?

The Kalmar Battery Monitoring System continually monitors the voltage, temperature, coolant and current flow of your battery solution to ensure that it operates optimally over its lifetime, managing the power for you. This system also controls the charging of the batteries by redirecting recovered energy back into the battery packs, making sure you are using the power available as efficiently as possible. This information is then accessible through Kalmar Insight.

What is green steel?

Green steel is just as strong and resilient as traditionally made steel however the carbon used during its production is significantly less. Green steel is made from recycled steel and produced using fossil free electricity and biogas which significantly reduced the carbon emission produced.